Wheels and castors for food processing industries

Jul 13, 2021

Reading time: minutes

Industrial wheels, depending on the trolleys on which they are mounted, play a fundamental role in moving materials. The focus becomes even greater when it comes to heavy duty in different areas of use.

Below we will list a series of expedients in order to assess the proper handling of goods within production facilities, as well as extraordinarily important aspects regarding safety at work.

When considering the problems related to the handling of goods, very often we begin with the configuration and design of the trolley, neglecting the analysis of the wheels that are applied to it, the choice of which is however fundamental for its subsequent use.

The choice of the wheel to be applied is normally made taking into consideration only the applied load.

However, it is not enough to have a trolley capable of carrying a given load because the human component is missing. The trolley must then be moved, pushed or pulled by the operator in the simplest and most congenial way possible.

The determining factors in the choice of wheels, in addition to type and amount of weight to be carried, are:

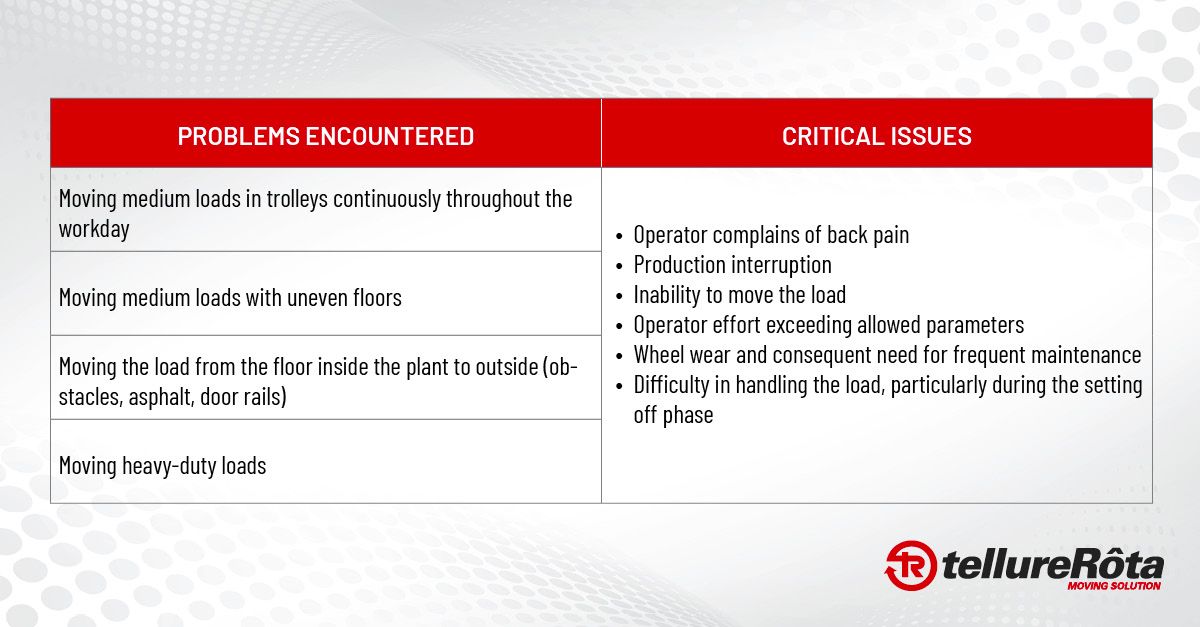

The many years of experience of a leading company in the field of industrial wheels such as Tellure Rôta have made it possible to identify different situations that involve critical issues common to all the situations described, as shown in the table below:

For almost 70 years, Tellure Rôta's core business has been the design and manufacture of wheels and castors for the industrial sector.

Tellure Rôta wheels are used for very different applications; this has allowed the company to acquire a high level of experience in the field of industrial internal handling.

Tellure Rôta has its own in-house research and testing laboratory, ‘TR Lab Test&Research’, accredited since 2011 to the Emilia-Romagna High Technology Network and included in the INTERMECH network of the University of Modena and Reggio Emilia.

Being part of networks of excellence allows TR Lab to constantly exchange multidisciplinary skills and experiences.

In this context, TR Lab has developed tools that have made it possible to deepen our knowledge of wheel behaviour: algorithms for simulating the functional behaviour of the wheel as a function of physical parameters that lead to wheel degradation, such as temperature, speed and load, which make it possible to prevent wheel behaviour under certain conditions of use.

In addition to research activities, TR Lab carries out tests on industrial wheels and castors, as well as elastomeric, thermoplastic and metallic materials. The wheel tests comply with the regulations for the wheel industry in general and those specific to the industry in which the wheels are used (such as the regulations for waste bin container wheels and the regulations for mobile scaffolding wheels).

Through the laboratory and the numerous experiments carried out in major industrial plants, Tellure Rôta's technical and design department has developed products capable of solving many of the critical issues reported, preventing - in terms of safety at work - the risks of accidents in the manual handling of loads.

These are particularly heavy-duty wheels with elastic ‘TR-Roll’ polyurethane coating with rounded ergonomic profile, available with either an aluminium (series 62ER) or nylon centre (series 62NY).

These wheels allow:

There is also a version with TR polyurethane covering (65ER series), which is suitable for manual handling of even heavier loads but only on regular floors.

In addition to the solutions described above, TR Lab and the Tellure Rôta design team will be happy to advise you on the best configuration of trolleys, wheels and castors for smooth handling according to your specific requirements.

Want to learn which types of industrial wheels are best suited to your specific needs, through a dedicated consultation? Contact our technicians to receive a no-obligation consultation for your specific project.