Wheels and castors for food processing industries

Jul 20, 2022

Reading time: minutes

Anyone who believes that automated guiding vehicles are a recent technological achievement is wrong. AGVs (Automated Guided Vehicles) have been used widely in industry since the 1950s. The term refers to a very broad category of vehicles that are able to move and operate independently without a driver.

Most AGVs are fitted with battery-powered electric motors, the size of which can vary greatly depending on the mode of operation and whether they are used to transport small items or up to loads of over 100 tons.

Over the years, AGV technology has changed with the introduction of increasingly sophisticated on-board software that controls individual vehicles as well as traffic management software for situations in which several automatic guided vehicles operate in the same location.

As regards their functions, these vehicles can pick up and deliver pallets and transfer loads automatically using forks, roller conveyors and lifting platforms according to the type and size of the units to be handled. The latest generation AGVs can be fitted with robotic arms and grippers to perform complex operations, such as storing materials up to a height of 10 metres, or even more in some cases.

It is an undisputed fact that the use of AGVs over the last few years, especially in warehouses, has led to a significant increase in efficiency together with increasing the space available for logistics.

AGVs have allowed companies to minimise the distance between shelves, as they no longer need to use forklift trucks or other bulky vehicles.

In view of this development, the industrial wheels and castors segment for AGVs has also had to adapt to the needs of the market and to the different situations in which they are used, ranging from closed working environments, such as offices with ceramic floors or surfaces that can be damaged, to outdoor industrial areas with uneven or even steep terrain and presence of obstacles.

Tellure Rôta's extensive experience in the industrial wheels sector has allowed it to identify some requirements that are common to all applications, leading to the design and production of wheels particularly suitable for AGVs, as well as for AMRs and other robotic systems.

Some of the main requirements of the sector include:

With these prerequisites in mind, the Formigine (MO) based company has developed some ad hoc solutions for the automatic guided vehicle sector, both for drive wheels and load/support wheels. We are referring to:

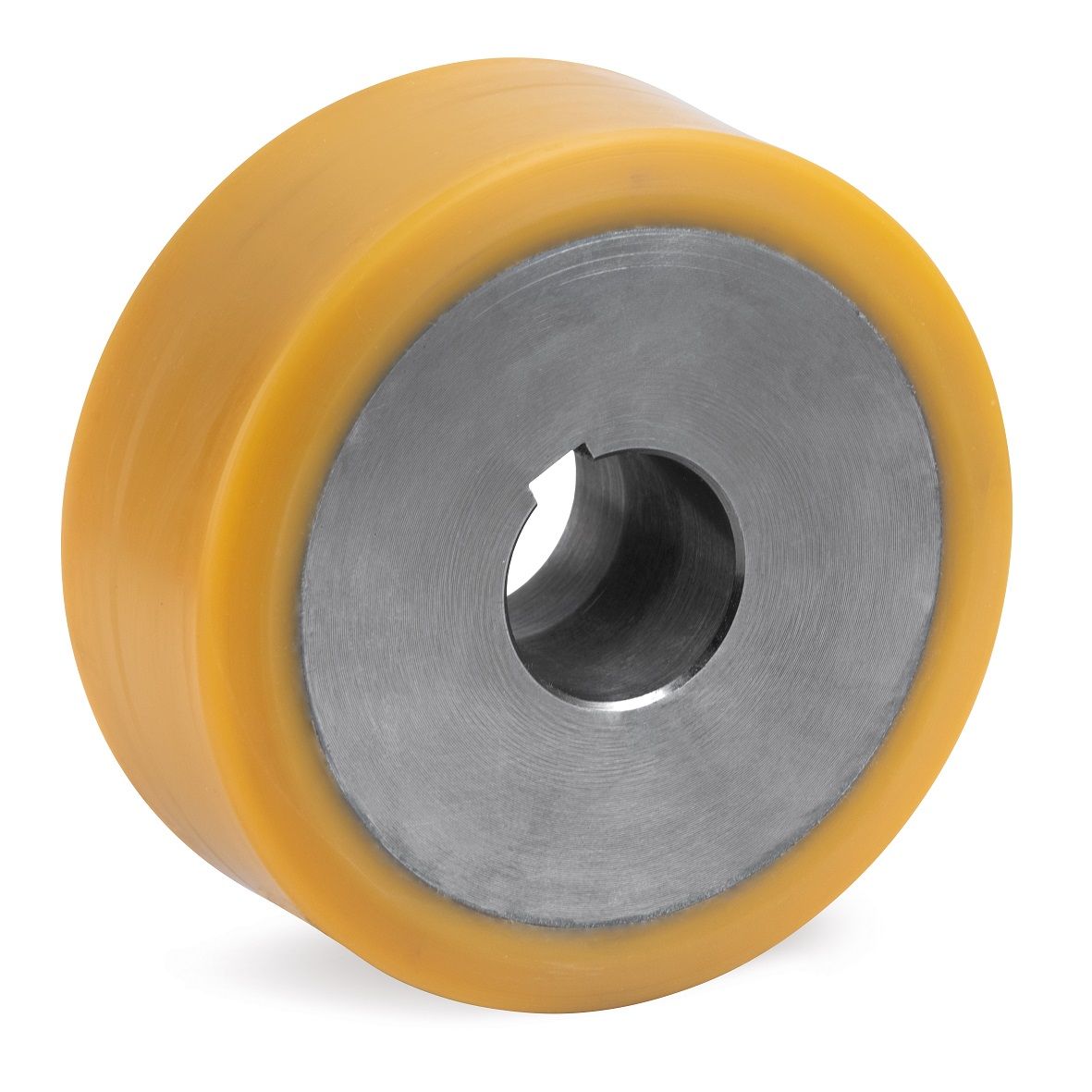

- High-performance Vulkollan® and TR polyurethane drive wheels that can be used in heavy duty high speed applications

- Solutions with rugged treads or solutions that use specific polyurethane compounds aimed at ensuring the AGV has an excellent grip when accelerating, braking, cornering and, in particular, when travelling on damp surfaces. Wheels that are particularly suitable for use in the food industry, galvanic environments and for outdoor use.

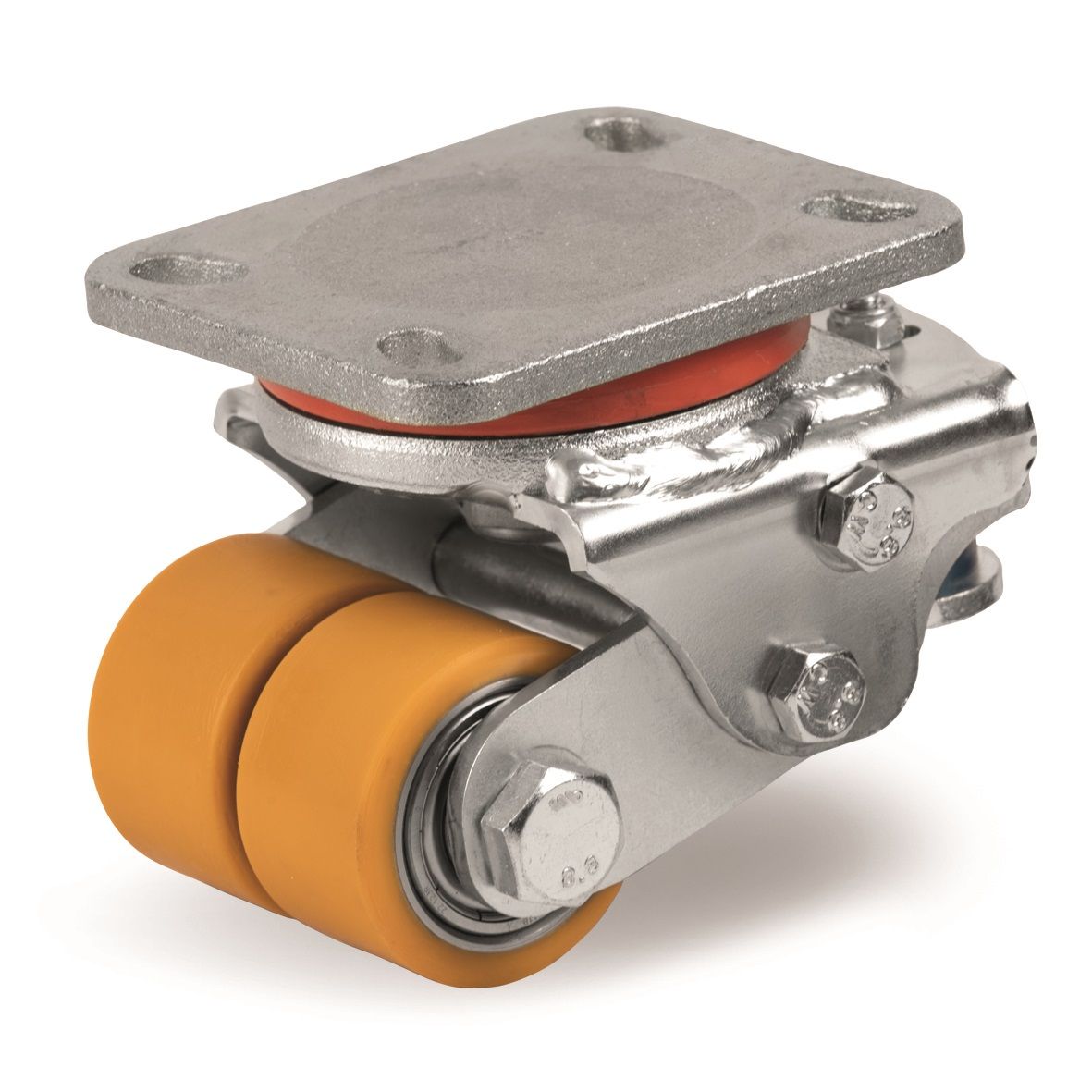

- Small diameter polyurethane wheels and specific low-profile castors, with a high load capacity and low turning radius, in order to limit the height of the AGVs and the space occupied by the wheels as far as possible.

Tellure Rôta manufactures these types of wheels and accessories using very high precision processes, both in terms of the metal parts and the shape of the tread.

This means that the wheels rotate precisely and smoothly and therefore minimize errors in automatic guided vehicle control systems.

Tellure Rôta’s expertise is not limited to the solutions described above. If our products for AGVs and AMRs do not meet company's specific needs, the staff at our TR Lab – Tellure Rôta's advanced in-house Test&Research laboratory – can work in close collaboration with the customer to provide customised solutions to overcome specific handling issues.

Want to learn which types of industrial wheels are best suited to your specific needs, through a dedicated consultation? Contact our technicians to receive a no-obligation consultation for your specific project.